M type brake back plates

Moderators: Ian Grace, Will Grace

M type brake back plates

Can someone tell me are the front and rear brake backplates of an M type the same? I recently purchased a spare rear axle for an M type but the brake operating levers on the spare axle are the same as the brake levers on the front of my car. The levers on the back of the car have the pinch bolt at right angles to the lever arm, the levers at the front of the car have the pinch bolt set at an angle. Perhaps someone has swapped levers around or may the entire backplate assembly.

Re: M type brake back plates

Derek,

There are several variants of the brake cam levers fitted to Minors/M Types and other MG's.

The early levers were almost straight, probably leaning over about 10 degrees from the vertical.

The SV Minir had levers at about 25 degrees, allowing the not to go past the vertical under braking. The M Type used the same levers as the equivalent contemporary Minors.

Later in, subsequent MMM cars used levers with even more if a lean, probably close to 40 degrees.

I suspect that your rear axle is from an early Minor or M.

By 1931, the SV Minor had been introduced which is why your M has the later type brake cams.

There are several variants of the brake cam levers fitted to Minors/M Types and other MG's.

The early levers were almost straight, probably leaning over about 10 degrees from the vertical.

The SV Minir had levers at about 25 degrees, allowing the not to go past the vertical under braking. The M Type used the same levers as the equivalent contemporary Minors.

Later in, subsequent MMM cars used levers with even more if a lean, probably close to 40 degrees.

I suspect that your rear axle is from an early Minor or M.

By 1931, the SV Minor had been introduced which is why your M has the later type brake cams.

Re: M type brake back plates

I should add a couple of quick comments.

First, the SV Minor brake drums were larger in diameter to accommodate the broader webs on the later brake drums. The M Types followed suit, regardless of the cast alloy fins.

Second, the brake cam levers on the front have a definite twist to the clevis pin eye which makes them handed, and also means that they should not be switched with levers from a back axle. This is necessary to line up the cable fork ends with the pulleys.

First, the SV Minor brake drums were larger in diameter to accommodate the broader webs on the later brake drums. The M Types followed suit, regardless of the cast alloy fins.

Second, the brake cam levers on the front have a definite twist to the clevis pin eye which makes them handed, and also means that they should not be switched with levers from a back axle. This is necessary to line up the cable fork ends with the pulleys.

Re: M type brake back plates

Thanks Ian

Nothing is ever simple! Maybe we need a brake lever identification table. Interesting to learn SV Minors had larger diametter brake drums. I shall measure mine at the weekend. Back to the original question though; are the front and rear back plates the same?

Nothing is ever simple! Maybe we need a brake lever identification table. Interesting to learn SV Minors had larger diametter brake drums. I shall measure mine at the weekend. Back to the original question though; are the front and rear back plates the same?

Re: M type brake back plates

Yes!

But just remember that the backplates on your spare axle are likely to be small diameter while the ones on your 1931 M are likely to be large diameter. You can't use the early backplates with the later brake drums.

But just remember that the backplates on your spare axle are likely to be small diameter while the ones on your 1931 M are likely to be large diameter. You can't use the early backplates with the later brake drums.

Re: M type brake back plates

Thank you Ian

The brake levers on the rear back plates fitted to the car have striaght levers. The spare axle has levers inclined at roughly 25degrees -the same as the front. That is why I thought maybe backplates from a front axle had been fitted to a back axle. I will measure up the drums this weekend. I shall probably start my rebuild by overhauling the spare back axle; it is useful to be able to move the car about on its wheels so a spare axle is rather handy.

The brake levers on the rear back plates fitted to the car have striaght levers. The spare axle has levers inclined at roughly 25degrees -the same as the front. That is why I thought maybe backplates from a front axle had been fitted to a back axle. I will measure up the drums this weekend. I shall probably start my rebuild by overhauling the spare back axle; it is useful to be able to move the car about on its wheels so a spare axle is rather handy.

Re: M type brake back plates

Brake back plates again!

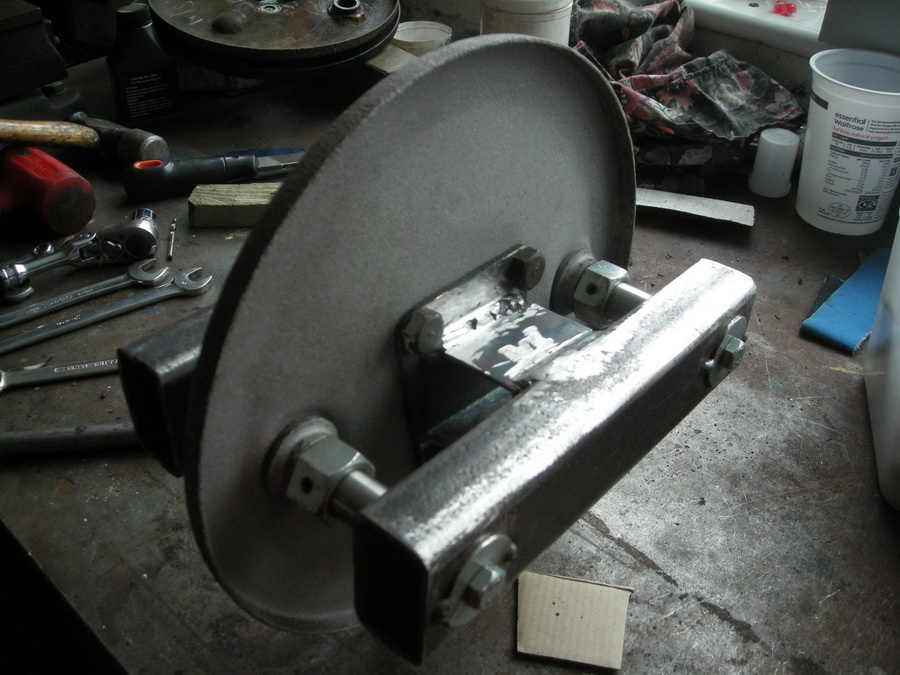

Is the problem shown in the attached photo. Both the brake cam and the brake shoe pivot pin are twisted with respect the back plate. I could heat the back plate and bend it back to bring it square but should I consider stiffening the part?

Is the problem shown in the attached photo. Both the brake cam and the brake shoe pivot pin are twisted with respect the back plate. I could heat the back plate and bend it back to bring it square but should I consider stiffening the part?

- Attachments

-

- M type brake cam.jpg (144.59 KiB) Viewed 5882 times

Re: M type brake back plates

Common problem! They come loose and people braze them, not taking any care to square things up. We had a member recently who devised a jig to ensure welding up square. I'll have to search to find out who it was!

Re: M type brake back plates

It was Philip Butland:

viewtopic.php?f=6&t=1223&p=8750&hilit=backplate#p8750

I'll ask him if he has the jig for loan.

viewtopic.php?f=6&t=1223&p=8750&hilit=backplate#p8750

I'll ask him if he has the jig for loan.

Re: M type brake back plates

Yes, it was I!

The jig is completed, used and can be loaned if anyone wants to collect or pay the postage. My experience with these back plates falls into three categories, those that have been brazed or gas welded without a jig and are hopelessly distorted, those that are so corroded that the bushes are loose and are fit only for scrap, and the third category where they have not been tampered with, are in good condition regarding oxidation but are still badly distorted. This third category are worrying and have convinced me that the basic design is flawed and very under engineered, the material being too thin with no reinforcing and therefore likely to distort with high pedal pressure.

The jig was built using data from a pair of very corroded but otherwise unmolested backplates provided by Toby Sears. However inaccuracies crept in due to welding stresses and the lack of facilities to build the jig from large section solid bar and the use of square hollow section metal which is not always "square"! All I can say is that it's better than nothing, please bear this in mind if you wish to borrow it. I did think about reinforcing the insert areas with large steel washers but have not yet done this as I am not sure if the transfer of loads from one area to another will achieve anything positive.

In conclusion having spent many hours on this project and still being less than happy I am still considering changing to hydraulics!

PhilipB

The jig is completed, used and can be loaned if anyone wants to collect or pay the postage. My experience with these back plates falls into three categories, those that have been brazed or gas welded without a jig and are hopelessly distorted, those that are so corroded that the bushes are loose and are fit only for scrap, and the third category where they have not been tampered with, are in good condition regarding oxidation but are still badly distorted. This third category are worrying and have convinced me that the basic design is flawed and very under engineered, the material being too thin with no reinforcing and therefore likely to distort with high pedal pressure.

The jig was built using data from a pair of very corroded but otherwise unmolested backplates provided by Toby Sears. However inaccuracies crept in due to welding stresses and the lack of facilities to build the jig from large section solid bar and the use of square hollow section metal which is not always "square"! All I can say is that it's better than nothing, please bear this in mind if you wish to borrow it. I did think about reinforcing the insert areas with large steel washers but have not yet done this as I am not sure if the transfer of loads from one area to another will achieve anything positive.

In conclusion having spent many hours on this project and still being less than happy I am still considering changing to hydraulics!

PhilipB

Re: M type brake back plates

And here's the jig:

Re: M type brake back plates

Interesting, certainly a sturdy jig. I intend to make some calculations to establish just how overstressed the back plate/pivot pin boss is. No point putting the boss back straight and then it happens again.

Seem s there are a few things abut the M type/ Minor that are not as good as they might be; wheels seem a particular problem.

Seem s there are a few things abut the M type/ Minor that are not as good as they might be; wheels seem a particular problem.