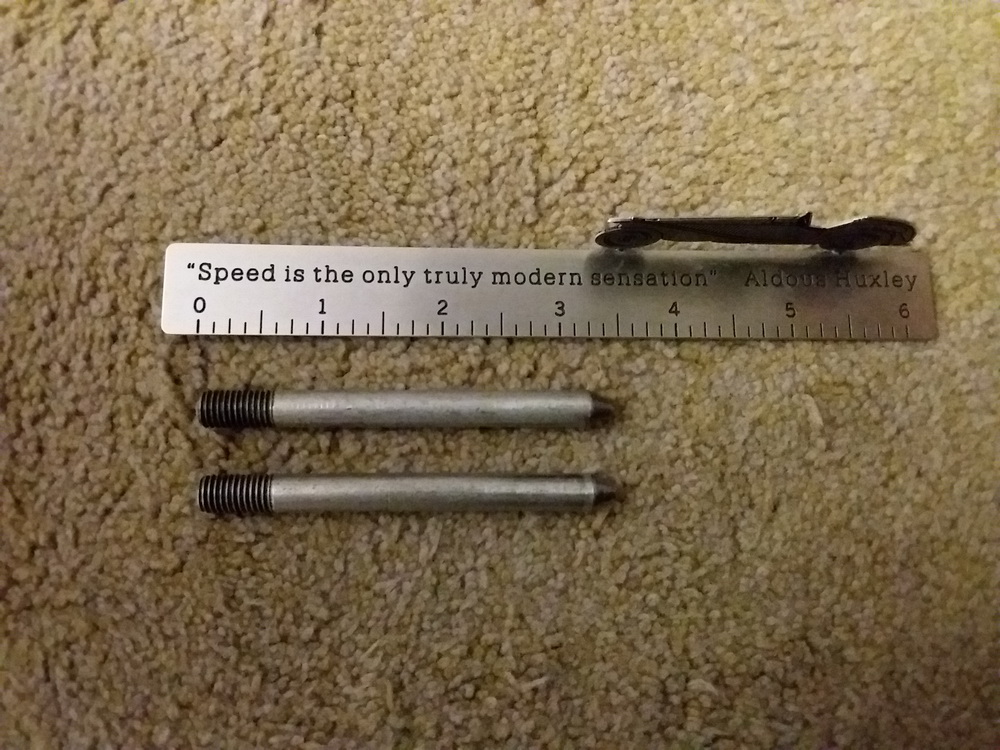

They are made from 5/16th BSF bolts, the heads being turned off to form a blunt cone.

With the clutch the pins are screwed into the flywheel, the engine side of the clutch is hung on the pins. It is then possible to place the clutch plate and a dummy to align the splines without having to support the weight of the whole assembly. Then the bolts may be put in place and tightened, the two pins being replaced by retaining bolts.

Another tip is to have secured the clutch springs in the alloy carrier with a little silicone glue, This saves the frustration of a spring dropping out during assembly.

When replacing the bellhousing/gearbox the pins are screwed onto two of the threaded holes on the back of the crankcase. Again it allows the weight to be taken whilst the unit is being bolted up.

I hope this tip will help someone faced with task which, without the pins is very heavy work.