Page 1 of 5

A gearbox rebuild

Posted: Sat Oct 13, 2012 3:05 pm

by Ian Grace

Having stripped down the McEvoy last weekend, I now have the gearbox sitting on the garage floor. It is a 4-speed crash box with Derrington remote and I plan to completely rebuild it. However, having owned about thirty Minors and rebuilt several of them over the last 35 years, I have never stripped a Minor (or any other) gearbox. So I thought I'd tackle it myself instead of sending it out so that I can learn how it is done. Then I thought that it might be of interest to record the rebuild in detail here on the forum, with photos, etc. so the thread can build into a reference for future rebuilders.

But I will need help. So first, has anyone here rebuilt a Minor box before, and could anyone point me to any reference material that might help - in the MMM Yearbooks perhaps? Later today, I'll post some photos of the box and remote as they have come out of the car. All input, suggestions and comments most welcome.

Re: A gearbox rebuild

Posted: Sat Oct 13, 2012 5:14 pm

by Toby

I have heard tales of woe regarding the taking apart of the synchro boxes but presumably that won't apply

Re: A gearbox rebuild

Posted: Sat Oct 13, 2012 10:22 pm

by Ian Grace

Let's hope I don't regret pulling this one apart!

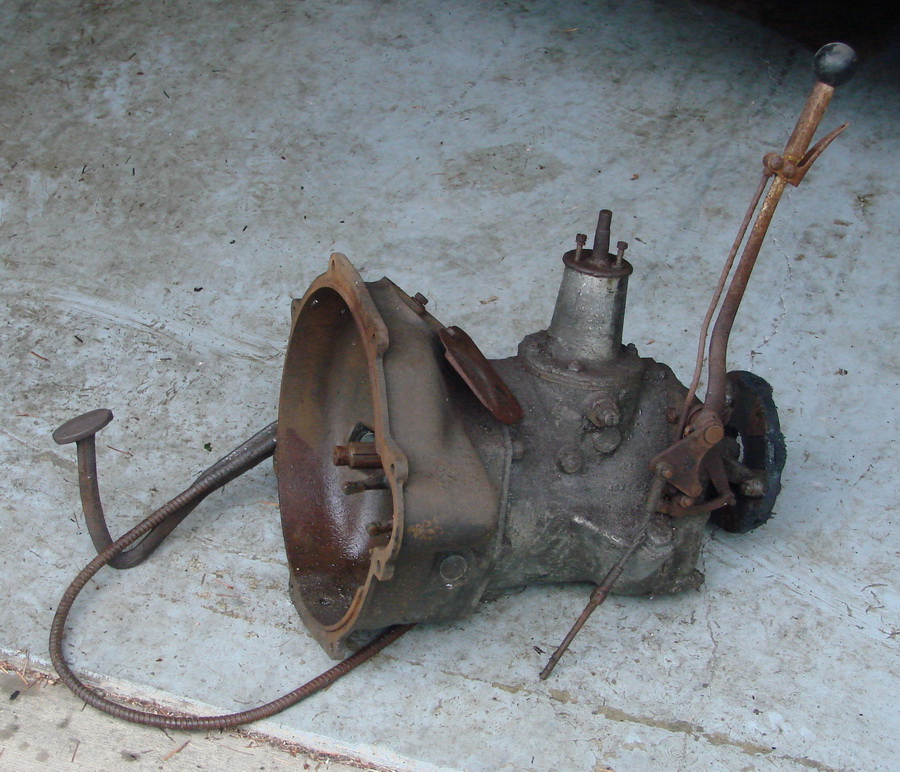

So here's the starting point:

The first task will be to remove the handbrake lever (which is slightly bent), the old fabric coupling (I have a new hardy Spicer prop shaft to fit), and then the serious dismantling can commence.

And here is the Derrington remote.

Re: A gearbox rebuild

Posted: Sat Oct 13, 2012 10:31 pm

by Trevor Wilkinson

I have sent you some instructions to your e-mail regarding dismantling a four speed box,it also says that re assembly is taken place in the reverse order!!

Should be simple.

Re: A gearbox rebuild

Posted: Sun Oct 14, 2012 9:07 am

by ian judd

If it was me, I would leave well alone! Give the outside a good clean, drain any old oil out and re-fill. Generally, these boxes are bomb proof and yours hasn't been used for decades, so there is still a very good chance that it's in excellent condition. The old adage comes to mind - if it ain't broke, don't fix it. For a start, if you don't know anything about the insides,you won't be able to recognise a fault anyway. Please try it on the road first!

Ian

Re: A gearbox rebuild

Posted: Sun Oct 14, 2012 3:49 pm

by Ian Grace

Hi Ian,

Interesting angle, and one I often advocate for engines, back axles, etc. And I know that these Minor boxes are pretty bullet proof. So I might clean it up, drain it, check for metal in the oil, take the top off and take a look at the visible teeth and shafts for overall wear, and also snick it into the various gears and see how it feels, so I know if the bearings are performing their design function.

My one concern is the wear on the input shaft which I'd like to sort. I don't think there is a source of new input shafts for these boxes, but I do know that the splines can be built up with weld and re-machined (actually a hobbing process). Either way, I'd have to split the box to get replace the shaft, so I might as well go through it if it is already in pieces.

OR, I could accept the wear. I have heard for years that spline wear can be so bad that the step on the splines prevents de-clutching. However, I'm not so sure this is not an old wives' tale. The movement of the driven plate on the splines cannot be much at all, and unless there is a very distinct step at the front end of the worn region preventing the driven plate from moving forward, I'd be surprised if the plate was prevented from moving enough to stay engaged with the rear clutch plate when the clutch pedal is depressed. I'll see if I can take a close-up of the wear and post it here shortly.

There are a lot of Minors and M Types driving around that must have worn input shafts and I don't hear that this is a serious problem. I'll see if I can take a close-up of the wear and post it here shortly.

Re: A gearbox rebuild

Posted: Sun Oct 14, 2012 4:01 pm

by Ian Grace

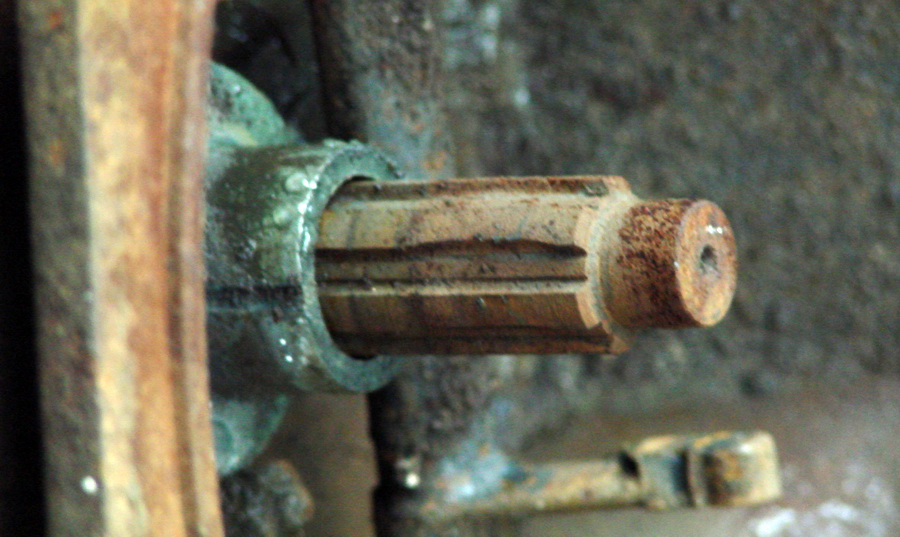

Here's the splines. I've seen worse, and there is no distinct step at the end of the wear regions.

Re: A gearbox rebuild

Posted: Sun Oct 14, 2012 8:36 pm

by ian judd

Well, that looks horrible! I can see why you might want to take it all apart. But as you say, there are worse splines being used.

I think the only successful repair is hard chroming and then regrinding. Building up with weld is ok to start with but the heat involved affects the rest of the hardening so the splines disintegrate. I believe this happened to Highlander.

Re: A gearbox rebuild

Posted: Sun Oct 14, 2012 10:00 pm

by Ian Grace

Ian,

It looks horrible partly because the engine was removed from the car some time in the fifties or sixties, but the gearbox was left in the chassis, so the front end has been exposed to the elements for decades.

I'll press on, cleaning it up externally, checking the internals as far as I can, and then come to a decision.

In the meantime, if anyone knows of an establishment who could take on the chroming and regrinding of the input shaft, I'd be very grateful.

I am also looking for a replacement clutch cross-shaft. Mine was cut off outboard of the clutch pedal to accommodate the hydraulic brake master cylinder which has its own brake pedal shaft. I'm reverting to cable brakes. Does anyone have a spare, unmolested cross-shaft?

3 p.m. Sunday here, and just completed M 143. Phew! Now I can get back to the garage.

Re: A gearbox rebuild

Posted: Sun Oct 14, 2012 11:52 pm

by Ian Grace

Clean-up started. Here are the stamped numbers. Can anyone decode?

9602/74 and 3/12. Is the 3/12 the SV speedometer drive gear ratio?

Presumably 9602 is the serial number of the gearbox.

There is residual black paint on the box - I believe they were never bare aluminium when new. I'll be painting the steel bell housing, but probably not the alloy gear housing.

My gut feeling is that I will clean up and install the box as is, without stripping or worrying about the worn splines.

Re: A gearbox rebuild

Posted: Mon Oct 15, 2012 10:27 am

by Trevor Wilkinson

" Is the 3/12 the SV speedometer drive gear ratio?"

Or is it gear selector position?

Re: A gearbox rebuild

Posted: Mon Oct 15, 2012 1:00 pm

by Flemming

It's no "old wives' tale" that the splines can be so worn that they prevent de-clutching.

The splines on our '34 two seater (4 speed with synchromesh on at least 3rd and 4th - not sure about 2nd) is visibly much more worn that yours.

It didn't really cause problems until we change the clutchplate (which was cracked) and the clutchplate hub with new parts from S&V.

Since then we have had severe trouble de-clutching when there is "pull" - in normal traffic on level road its no problem, but parking on non level grounds is a knigthmare.

I guess the old clutchplate hub was worn to suit the splines!

So I'd also be very interrested if anyone knows someone who can re-build the splines.

Flemming.

Re: A gearbox rebuild

Posted: Mon Oct 15, 2012 4:03 pm

by plj

Ian,

Is the clutch cross-shaft interchangeable between 3 and 4 speed boxes?

Philip

Re: A gearbox rebuild

Posted: Mon Oct 15, 2012 4:33 pm

by garagiste

Ian,

Please could we have a photo of the top of the gate, lever end, of the Derrington remote?

I have one that has four holes to screw a gate into position, I had alway assumed it to be a three speed bolt on goody.

Thanks.

Re: A gearbox rebuild

Posted: Mon Oct 15, 2012 6:37 pm

by Ian Grace

Philip,

I believe so. Haven't checked the parts lists, but I see no reason for it to be different in any significant way.

David,

Will do,

Ian