A gearbox rebuild

Moderators: Ian Grace, Will Grace

Re: A gearbox rebuild

The top 2 images from David show a D-type 3-speed remote.

I have one on my M - works a treat

BTW, Ian, I would have bored you with a pic on my gearbox top but can't find how to attach an image - some clues please, as clicking in the "Img" button just produces gibberish

Tony

I have one on my M - works a treat

BTW, Ian, I would have bored you with a pic on my gearbox top but can't find how to attach an image - some clues please, as clicking in the "Img" button just produces gibberish

Tony

-

Sam Christie

- Posts: 186

- Joined: Mon Nov 20, 2006 10:37 am

Re: A gearbox rebuild

Here is an example Tony (a good copy actually) .  Photo by GW

Photo by GW

Photo by GW

Photo by GWRe: A gearbox rebuild

Tony, check your e-mail.tonym wrote: BTW, Ian, I would have bored you with a pic on my gearbox top but can't find how to attach an image - some clues please, as clicking in the "Img" button just produces gibberish

Tony

Ian

-

Sam Christie

- Posts: 186

- Joined: Mon Nov 20, 2006 10:37 am

Re: A gearbox rebuild

In answer to an earlier question the 3/12 on the top of the gearbox relates to the speedometer drive. In this case it will have 12 teeth.

The example below has 17 teeth.

And it fits this gearbox - though I confess I do not know which model it comes from - perhaps it can be identified ?

The example below has 17 teeth.

And it fits this gearbox - though I confess I do not know which model it comes from - perhaps it can be identified ?

Last edited by Sam Christie on Wed Nov 07, 2012 7:32 pm, edited 1 time in total.

Re: A gearbox rebuild

Thanks for confirming this, Sam. I think all of the OHC Minor boxes are 4/17.

-

Sam Christie

- Posts: 186

- Joined: Mon Nov 20, 2006 10:37 am

Re: A gearbox rebuild

Ian, I have just checked the four speed non synchromesh gearbox which was on my M-type when I bought it and it is stamped 4/17 (not its original three speed) and the speedometer readings ,with a standard OHC/M-type back axle ratio and an M-type speedometer,seem to be reasonably correct .

Presumably a three speed OHC Minor/M-type gearbox has a similar speedometer drive ? Am I right to assume that the same three speed gearbox (with the same gearing and speedometer drive ratio) was used on the SV Minor and the different rear axle ratio compensated for with a different speedometer?

Presumably a three speed OHC Minor/M-type gearbox has a similar speedometer drive ? Am I right to assume that the same three speed gearbox (with the same gearing and speedometer drive ratio) was used on the SV Minor and the different rear axle ratio compensated for with a different speedometer?

Re: A gearbox rebuild

Sam,

I think you could be right - 4/17 for the white faced speedos, 3/12 for the smaller SV moving disk type speedo. Presumably the 3 and 4 refer to the number of teeth on the spiral drive gear.

Ian

I think you could be right - 4/17 for the white faced speedos, 3/12 for the smaller SV moving disk type speedo. Presumably the 3 and 4 refer to the number of teeth on the spiral drive gear.

Ian

Re: A gearbox rebuild

This just in from Tony Margel:

"The attachment is my D-type remote – don’t seem to have a better one at the moment. Currently the top is being re-built as it is crumbling away at the gear lever end! Also in the pic – the floor mats are £2 bath mats cut to shape – this is a Yorkshire car after all and the foot board is ex Bradford Corporation bus!

Best wishes

Tony"

"The attachment is my D-type remote – don’t seem to have a better one at the moment. Currently the top is being re-built as it is crumbling away at the gear lever end! Also in the pic – the floor mats are £2 bath mats cut to shape – this is a Yorkshire car after all and the foot board is ex Bradford Corporation bus!

Best wishes

Tony"

-

Mike Stubbings

- Posts: 196

- Joined: Thu Dec 27, 2007 5:41 pm

Re: A gearbox rebuild

Hi All,

Back in the 60s I had just rebuilt a BSA SCOUT with the same sort of wear on the front drive shafts, I was told they would be ok but a couple of days having the car on road test they gave up. I removed them with the intention of getting them built up with weld. I was told it would not last long unless done correctly. At the time Ron Flockhart had a garage business next door to where I lived. I asked him what he thought and

it was suggested I leave them with him. They were returned in a couple of days looking great having been welded and remachined. I refitted them and I ran the car daily for about two years without any trouble. I cannot say how long they lasted as I lost touch with the car. If you have them welded make sure you have someone do it who knows what they are doing. Good luck, Mike

Back in the 60s I had just rebuilt a BSA SCOUT with the same sort of wear on the front drive shafts, I was told they would be ok but a couple of days having the car on road test they gave up. I removed them with the intention of getting them built up with weld. I was told it would not last long unless done correctly. At the time Ron Flockhart had a garage business next door to where I lived. I asked him what he thought and

it was suggested I leave them with him. They were returned in a couple of days looking great having been welded and remachined. I refitted them and I ran the car daily for about two years without any trouble. I cannot say how long they lasted as I lost touch with the car. If you have them welded make sure you have someone do it who knows what they are doing. Good luck, Mike

-

Sam Christie

- Posts: 186

- Joined: Mon Nov 20, 2006 10:37 am

Re: A gearbox rebuild

Just a quick apology and correction. Having consulted with a much wiser council I find this gearbox is in fact a non-synchromesh example .

Apparently the distance from the rear of the selector mounting to the back of the casing (where 4/17 appears in the picture below) is similar to the distance at the front (where 11804/110 appears in the picture below) on a non-synchromesh box. On the gearbox below the gap at 11804/110 is much bigger than the gap at 4/17 which shows it is indeed a synchromesh example.

I think my measurements of the casing lengths quoted earlier are still roughly correct.

And to go one better here is a non-synchromesh gearbox top which underlines the point.

Apparently the distance from the rear of the selector mounting to the back of the casing (where 4/17 appears in the picture below) is similar to the distance at the front (where 11804/110 appears in the picture below) on a non-synchromesh box. On the gearbox below the gap at 11804/110 is much bigger than the gap at 4/17 which shows it is indeed a synchromesh example.

I think my measurements of the casing lengths quoted earlier are still roughly correct.

And to go one better here is a non-synchromesh gearbox top which underlines the point.

Last edited by Sam Christie on Thu Nov 08, 2012 9:50 am, edited 1 time in total.

-

Jpallis001

- Posts: 207

- Joined: Sun Nov 07, 2010 8:08 pm

- Location: Durham

Re: A gearbox rebuild

Thanks Sam, that does explain why I do have to be careful when changing both up and down gear. Has anyone any experience of trying to re-profile the bottom of the gear lever? what shape should it be?

John

John

-

Sam Christie

- Posts: 186

- Joined: Mon Nov 20, 2006 10:37 am

Re: A gearbox rebuild

I don't have one off a four speed gearbox to hand but this less deep example is from a three speed gearbox and gives an idea of how the tip of the gear lever normally looks. Perhaps another member can provide a four speed image?

- Attachments

-

- Gear lever tip three speed

- Screen Shot 2012-11-03 at 12.53.10.png (547.08 KiB) Viewed 7910 times

Re: A gearbox rebuild

1934 Minor 4-speed synchromesh box gear selector end profile. (with wear)

- Attachments

-

- gear1.jpg (85.51 KiB) Viewed 7902 times

-

- gear2.jpg (88.91 KiB) Viewed 7902 times

-

Sam Christie

- Posts: 186

- Joined: Mon Nov 20, 2006 10:37 am

Re: A gearbox rebuild

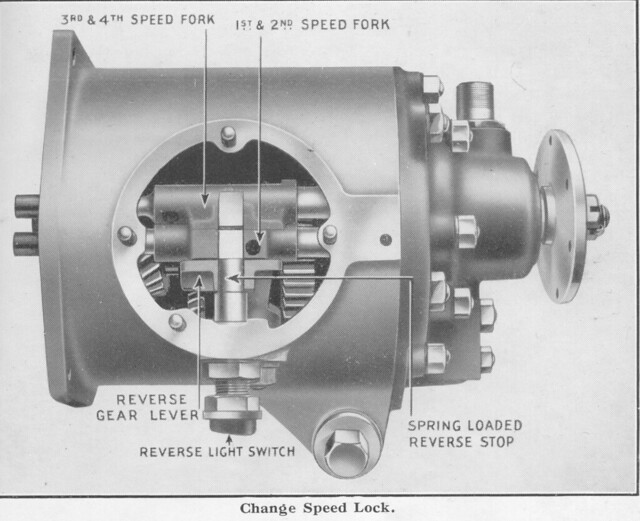

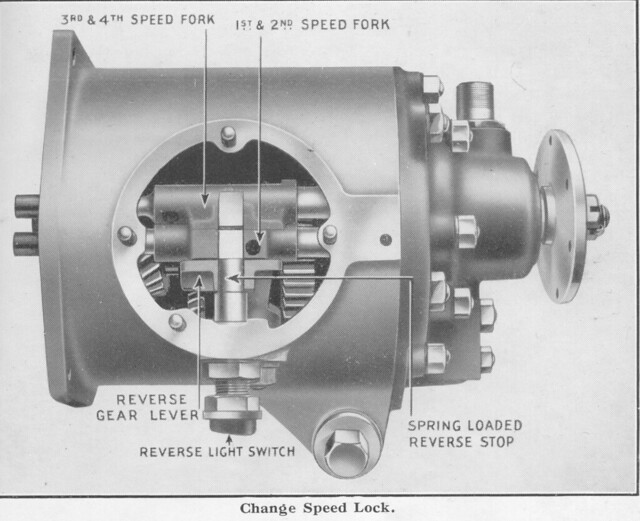

Some further pictures from a 1933 Wolseley Hornet Manual. I did not know about the reverse light switch.

Re: A gearbox rebuild

Well spotted Sam! I thought that was a modern idea.

A reverse switch would be really useful. But where to find one?!

Ian

A reverse switch would be really useful. But where to find one?!

Ian