Rear Axle.

Moderators: Ian Grace, Will Grace

Re: Rear Axle.

When you fit the rear hubs, they should have a felt washer and a thin steel washer/cup plate (for want of a technical term!) which the felt seal sits in. I have often found cards where this steel plate is absent. As for tightening the ring nut (with a locking tab washer under it), it should go at least flush with the end of the axle casing. The trick is to get it tight enough, but not so tight that you are crushing the felt seal which then does make the hub very difficult to turn as it acts as a brake - it isn't the grease doing it. For this reason, the felt seals should be soaked in oil before fitting.

-

Highlander

- Posts: 489

- Joined: Fri Nov 24, 2006 12:52 am

Re: Rear Axle.

Thank you Ian. I did not do much today only cut out the paper gaskets - a job I like. I am sure my hubs are standard. I do not have a felt washer but a modern plastic one, I have the thin plate washer you mention and then the bearing. When on the bench and you can get a close look the outer rim of the bearing is short of the back - I would have thought the plastic washer would crush to use a word - however the main problem is the inner part of the bearing which slides on the axle tube - this should I am sure go further back but does not! There is a large felt washer right at the back - is this what you mention?, the hub would press up against that. This felt washer, and I have one on each side, slides over the axle tube to the back and then the hub slides on and butts up to it. I am resting till after Christmas but want to get to Brooklands. Aye, Highlander.

Re: Rear Axle.

I'll give you a call before Christmas!

Ian

Ian

Re: Rear Axle.

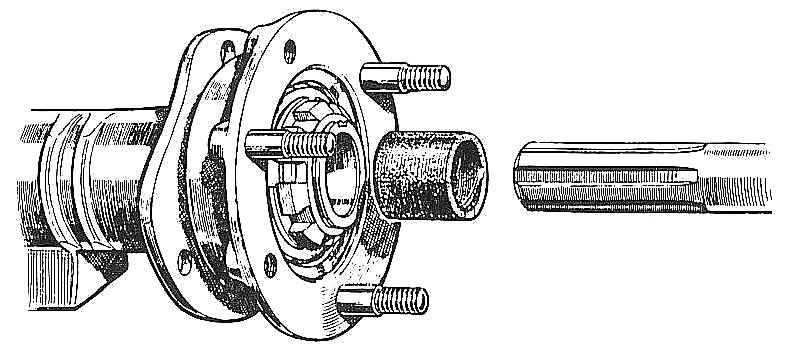

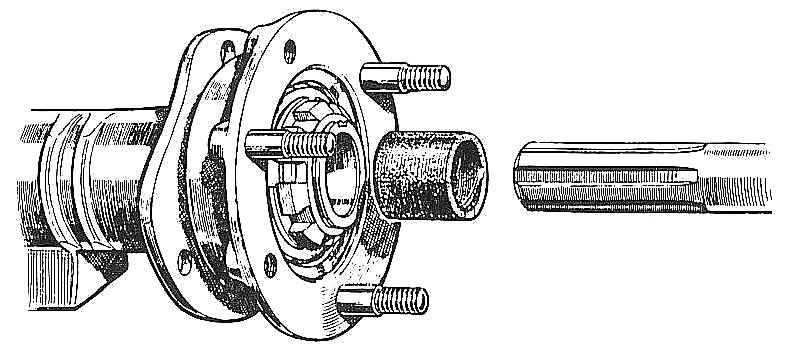

Hope thiese pictures help! I have just taken them, ok from the M type but the axle is the same.

There are a couple of styles of hubs and it sounds to me like you have the later one but that someone has tried to put the felt washer on in the early place as well as a modern seal - from where I am it sounds like the felt seal is your problem.

In the hub picture (sorry poor quality but then it is 6:47am) you can just see the felt inside the hub up against the bearing.

The axle end has a step that the bearing goes up against the felt sliding over the larger section but retained in the hub - no free or outside the hub.

Cheers

Jeremy

There are a couple of styles of hubs and it sounds to me like you have the later one but that someone has tried to put the felt washer on in the early place as well as a modern seal - from where I am it sounds like the felt seal is your problem.

In the hub picture (sorry poor quality but then it is 6:47am) you can just see the felt inside the hub up against the bearing.

The axle end has a step that the bearing goes up against the felt sliding over the larger section but retained in the hub - no free or outside the hub.

Cheers

Jeremy

- Attachments

-

- RearHub (3)a.jpg (65.69 KiB) Viewed 3496 times

-

- RearHub (2)a.jpg (51.42 KiB) Viewed 3496 times

-

Highlander

- Posts: 489

- Joined: Fri Nov 24, 2006 12:52 am

Re: Rear Axle.

Dear Jeremy and Ian, Thanks for the photos. On picture 2, the bearing in the hub with sight of fibre washer, I have a fat washer/spacer that fits into the hub and covers the seal. This washer is a very tight fit on the axle tube and I think this could be the problem, it sticks somewhere. I will have a fresh look after the holiday (Saturday). Another simple question - If the hubs are not far enought on the axle, what happens when I offer up the half shafts? Highlander.

Re: Rear Axle.

Ian, begging your pardon, ref your message on 23rd Dec. The nut holding the wheel bearing on to the axle casing should be DEAD tight and locked with the tab washer otherwise it could work loose and hub, brake drum, wheel and halfshaft become detached from the car (I have seen a picture of a Hornet / Minor possibly in VSCC/ Automobile to which this has happened, some time in the past). The felt washer can only be compressed so far on the early type hubs. I use the correct C spanner with a 12" tubular extension to do the nut up.

Re: Rear Axle.

The hub must be put on right otherwise it will work loose with probably quite upsetting consequences.

If the bearing inner race does not get clapmed against the step in the axle case it will move about, as it moves so will the halfshaft and the drum and the wheel. It will damage the axle case and if it came off through damage to the castle nut you might see your wheel with half shaft attached overtaking you just as you hear a sickening crunch which is the back of the car hiting the road!

Simon is quite right these nuts must be done up tight. If the hub does not turn there is something wrong possibly the felt seal in the wrong place or a damaged bearing.

Merry Christmas everyone,

Cheers

Jeremy

If the bearing inner race does not get clapmed against the step in the axle case it will move about, as it moves so will the halfshaft and the drum and the wheel. It will damage the axle case and if it came off through damage to the castle nut you might see your wheel with half shaft attached overtaking you just as you hear a sickening crunch which is the back of the car hiting the road!

Simon is quite right these nuts must be done up tight. If the hub does not turn there is something wrong possibly the felt seal in the wrong place or a damaged bearing.

Merry Christmas everyone,

Cheers

Jeremy

Re: Rear Axle.

Yes, quite right guys - the nut should be tight - I wasn't thinking when I wrote that! What I meant to say was that the bearing has to be pushed into the hub by just the right amount - too far and it compresses the felt seal too much. I usually offer the brake drum up and check that the drum fits snugly into the backplate.

If it isn't tight enough, then yes, the half shaft will not engage quite so far as it should into the diff, but the amount will be tiny compared to the length of the splines, and I wouldn't worry about that.

That fat washer/spacer sounds like someone's attempt to prevent oil getting onto the brakes and is non standard - there should just be the felt seal, plus, you can (and really should) fit axle shaft seals inside the casing, to stop the oil getting that far.

If it isn't tight enough, then yes, the half shaft will not engage quite so far as it should into the diff, but the amount will be tiny compared to the length of the splines, and I wouldn't worry about that.

That fat washer/spacer sounds like someone's attempt to prevent oil getting onto the brakes and is non standard - there should just be the felt seal, plus, you can (and really should) fit axle shaft seals inside the casing, to stop the oil getting that far.

Re: Rear Axle.

| have a Morris 8 hub bearing housing with a double row ball bearing (not sure whether it is a series 1 or 2 or E) but it came with a loose ring that fitted inside the hub against the neoprene type oil seal . Can only assume that the later type Morris 8 axle casings did not have a step to locate the bearing but used the loose ring ( probably made the axle casing cheaper to produce).

Highlander may well have mixture of bits if he has a loose ring - will give him a call tomorrow - Saturday.

Highlander may well have mixture of bits if he has a loose ring - will give him a call tomorrow - Saturday.

-

Highlander

- Posts: 489

- Joined: Fri Nov 24, 2006 12:52 am

Re: Rear Axle.

Managed two hours today in sunshine but b...y cold. Simon gave me a telephone call this morning with some tips and the two photo you have provided are a great help. I took both hubs off again. If you look at photo one of the back plate and axle tube mine is the same but I have this spacer (1/4"" thick) butting up to the shoulder of the axle tube. It come to the start of the tab washer groove. Chris states that the inner bearing should butt up to this shoulder. Why should mine be 1/4" nearer the lock nut?What I have done today is take these spacers off (not easy as there are a very very close fit on the shoulder) I put the hubs back on without them. I could get the lock nut done up flush with axle tube but when "tight" the bearing is hard to turn by hand but not bad with the wheel on. I offered up a half shaft and all seemed well. Why do I have a thick felt washer between the back plate and the hub? No oil or grease near it!!! I have my T model Ford man comming on Monday and we will do todays exercise again - two heads are better than one. I took great care when taking the hubs apart at the start to list and mark everything. These two spacers came off then and the car had gone for me for over 5 years, the only thing I cannot remember is how far on the axle tube the lock nut was. Ron Curtis from whom I purchased my minor was an aeronautical engineer so I hope he was not an bodgengineer!Still hope to get to Brook;lands - anyone else going? Highlander.

Re: Rear Axle.

This might help - taken from the service sheets in the Members' Area:

The ring nut holds the hub tight against the step on the axle sleeve. Behind the bearing, and inside the hub is the felt seal and steel washer. Depending on how tight the bearing is pressed into the hub will determine the position of the hub, and therefore the brake drum with respect to the backplate. If the bearing is not in far enough, the brake drum will not be fully seated in the back if the bearing is pressed in too far, then the felt seal will be squashed too tightly and act as a brake. (A similar situation applies for the front hub felt seals.)

This drawing also shows the cork seal mod. There should be no other seals present in a standard set-up.

The ring nut holds the hub tight against the step on the axle sleeve. Behind the bearing, and inside the hub is the felt seal and steel washer. Depending on how tight the bearing is pressed into the hub will determine the position of the hub, and therefore the brake drum with respect to the backplate. If the bearing is not in far enough, the brake drum will not be fully seated in the back if the bearing is pressed in too far, then the felt seal will be squashed too tightly and act as a brake. (A similar situation applies for the front hub felt seals.)

This drawing also shows the cork seal mod. There should be no other seals present in a standard set-up.

-

1936morriseight

- Posts: 35

- Joined: Sat Jan 12, 2008 12:59 pm

Re: Rear Axle.

Hi Alister,

Jeff Taylor here, Morris Register - Eight MVS Forum, I answered a couple of your posts the other week re your Eight diff unit.

Re your hubs, I fear the previous owner, possibly in an attempt to fit a modern oil seal in place of the felt - is what you describe as a 'plastic washer' actually a modern neoprene oil seal, which obviously needs a smooth parallel surface i.e. the 1/4" spacer ring to run upon?

To achieve this modification, it appears to me that he's incorporated a part from an Eight axle, namely this 1/4" spacer. As Simon suggests, unlike the Minor the Eight axle case does not have an integral stepped shoulder, but uses this spacer ring to serve the same dual purpose - a) to act as a smooth bearing surface for the felt and b) by means of the bearing nut, to nip the bearing inner race hard up against the axle case so it doesn't turn.

My suggestion would be to discard this spacer and the 'plastic washer' and re-assemble as per a standard Minor set up with a felt oil seal in place of this 'plastic washer' (don't forget the Felt Retaining Steel Cup Washer though). Standard set up should be as follows, I believe:

Bearing Nut, Bearing Nut Lock Washer, Bearing, Felt Seal Retaining Steel Cup washer, Felt Oil Seal, Steel Bearing Housing Carrying the Wheel Studs.

The bearing housing including bearing, felt and felt retainer is then pushed onto the axle casing with the bearing inner race hard up against the stepped shoulder - preventing the inner race from turning, before the nut lock washer and bearing nut are attached.

Perhaps if the previous owner had been able to machine off the Minor's stepped shoulder to resemble that of an Eight, then his modification may well have been more successful and more importantly safe. As it is, it would appear to me as if each of your rear wheels are approx 1/4" further out than they should be and perhaps more worrying, your bearing nuts may not be as fully tightened onto the threaded axle case as they were designed to be.

Finally there shouldn't be - neither on your Minor nor on an Eight, a thick felt washer between the back plate and the hub.

Hope this all helps.

Jeff

1936morriseight

Jeff Taylor here, Morris Register - Eight MVS Forum, I answered a couple of your posts the other week re your Eight diff unit.

Re your hubs, I fear the previous owner, possibly in an attempt to fit a modern oil seal in place of the felt - is what you describe as a 'plastic washer' actually a modern neoprene oil seal, which obviously needs a smooth parallel surface i.e. the 1/4" spacer ring to run upon?

To achieve this modification, it appears to me that he's incorporated a part from an Eight axle, namely this 1/4" spacer. As Simon suggests, unlike the Minor the Eight axle case does not have an integral stepped shoulder, but uses this spacer ring to serve the same dual purpose - a) to act as a smooth bearing surface for the felt and b) by means of the bearing nut, to nip the bearing inner race hard up against the axle case so it doesn't turn.

My suggestion would be to discard this spacer and the 'plastic washer' and re-assemble as per a standard Minor set up with a felt oil seal in place of this 'plastic washer' (don't forget the Felt Retaining Steel Cup Washer though). Standard set up should be as follows, I believe:

Bearing Nut, Bearing Nut Lock Washer, Bearing, Felt Seal Retaining Steel Cup washer, Felt Oil Seal, Steel Bearing Housing Carrying the Wheel Studs.

The bearing housing including bearing, felt and felt retainer is then pushed onto the axle casing with the bearing inner race hard up against the stepped shoulder - preventing the inner race from turning, before the nut lock washer and bearing nut are attached.

Perhaps if the previous owner had been able to machine off the Minor's stepped shoulder to resemble that of an Eight, then his modification may well have been more successful and more importantly safe. As it is, it would appear to me as if each of your rear wheels are approx 1/4" further out than they should be and perhaps more worrying, your bearing nuts may not be as fully tightened onto the threaded axle case as they were designed to be.

Finally there shouldn't be - neither on your Minor nor on an Eight, a thick felt washer between the back plate and the hub.

Hope this all helps.

Jeff

1936morriseight

-

Highlander

- Posts: 489

- Joined: Fri Nov 24, 2006 12:52 am

Re: Rear Axle.

Thank you all for the latest input re my back axle, especially Jeff for his detailed, step by step description of what should be done, and what I should do. I went out this morning, sunny but again very cold, aand if taking minor rear hubs apart was an Olimpic Sport I would be a gold medalist!!I started on the nearside rear. Five minutes and it was on the bench. The felt washer that was behind everything and of no use was taken off and cleaned. I dismantelled the hub and discarded the thick washera and the modern oild seal. I found that the felt washer was the right one for the hub so reassembled as per Jeff's instructions. The hub went on up to the back shoulder (now washerless) and the lock nut plus tab washer tightened up hard and the bearing spun like a good 'n. Filled with joy I started on the oddside rear. All came off easy enough and on the bench with the other felt washer. I had had trouble with this bearing before. It was loose when I first took it off. This bearing is a sod to press home and my vice is not big enopugh to press it home so I have towhack it home with a large block of hard wood and a hammer. When home it does not run freely and I have treid three times aand have given up. I may have damaged the bearing so I will take it to Sutton Rebore and get them to look at the bearing and if need be replace it and press it home for me. I have offered up the halfshaft on the nearside and it went home perfectley so if I get the other bearing sorted the next job will be offering up the new diff cage and - bingo Brooklands on the ist Thanks again everyone. Highlander.

Re: Rear Axle.

Further to my comments on 24th December please see the report on the VSCC Westcott Driving Tests, held in December 2003, in the VSCC Bulletin , Spring 2004. You have been warned !!!

-

Highlander

- Posts: 489

- Joined: Fri Nov 24, 2006 12:52 am

Re: Rear Axle.

Did not get to Sutton Rebore because of golf but this afternoon I took the hub and bearing to my model T friend who checked the hub for roundness - it was not round!!!! 3 to 5 thou out. He set it up on his lathe but could not get it "square" to turn the high-spots off. Rang Sutton and they will try somethying tomorrow. Question - How did a hub, with a bearing inside it, get bashed of knocked so badly as to damage it? Might be easier to find another hub but I do want to get to Brooklands on Thursday lst. PS we ppressed the bearing on with a large press. No problem except bearing would not run freely - pressed it out and ran like the wind!!QED for today Highlander.