Page 1 of 2

DF9053

Posted: Sun Dec 03, 2006 8:36 am

by DF9053

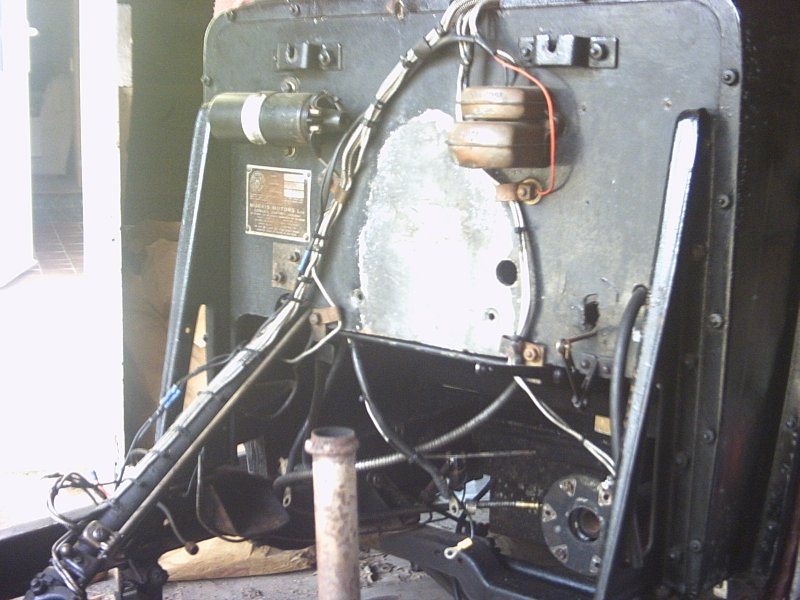

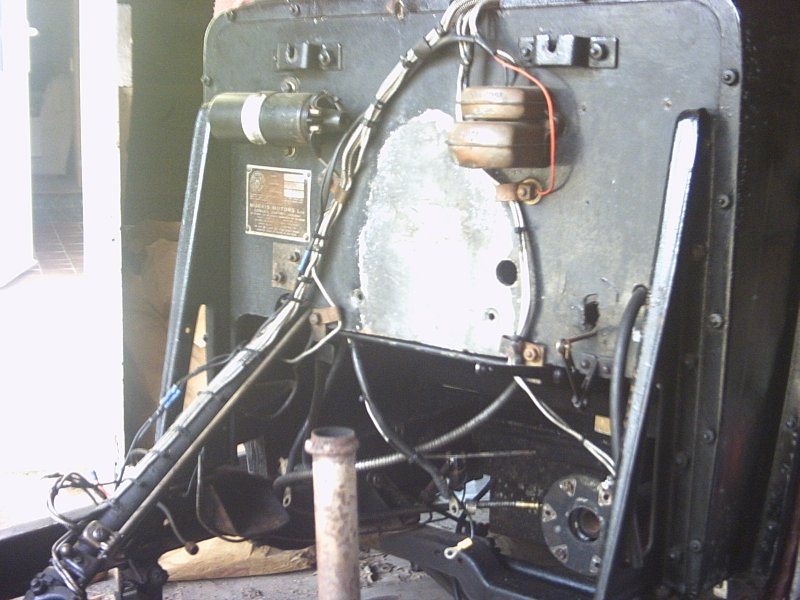

Whilst the engine of DF is out being rebuilt following the summer rally bearing problems, I thought I would do a few other jobs. Perhaps I got carried away!

Firstly there is the kingpins, shockabsorbers and front brakes

Then the front chassis and firewall may as well have the once over

and then I thought might as well tidy the front wings!

I am sorting the bonnet as well just for good measure!

cheers

Jeremy

Posted: Fri Dec 08, 2006 4:25 pm

by DF9053

The wings and bonnet are now with the spray shop, should get them back before Christmas.

In the mean time I can get the chassis painted up and looking good.

Does anyone know of a mail order company who deals in "topping" or another suitable roof material. Anyone who saw DF last year will know this is another job that needs doing!

Posted: Sun Jan 28, 2007 9:05 am

by DF9053

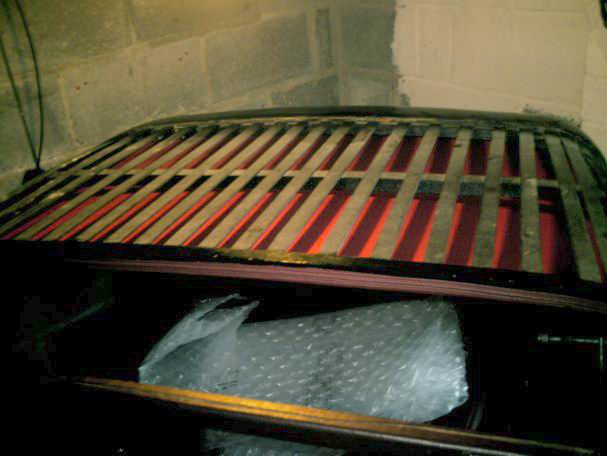

I now have the roof material in the garage and today's job is to strip the old material off and assess whether any repairs are needed to teh roof structure.

The chassis is not in top coat, although not the best paint drying weather! I hope to put another layer on before the rebuilding starts.

I'll put some more pictures up later.

Posted: Mon Jan 29, 2007 8:51 am

by DF9053

Here are some progress pictures

Chassis in primer ready for top coat.

Top coat looking smart, one more before reassembly, its taking ages to dry with the cold and wet weather - please excuse the leaves all over the floor!

Rear roof structure, the red is the inside of the headlining, there was a felt cover over the strips then the roof material.

This header rail has seen better days, thankfully it does not look difficult to make a new one.

Cheers Jeremy

Posted: Fri Feb 09, 2007 12:23 pm

by DF9053

Does anyone know whether I need to pull the "duck" fabric tight or leave room for shrinkage?

Front to back it is held but side to side, on the opening section, the last roof had shrunk quite a bit.

I have sourced some ash for a new header rail and once this is made hope to fix the material on.

Many thanks

Jeremy

Posted: Fri Feb 09, 2007 9:43 pm

by Ian Grace

I would give Dave Cooksey a call. He's going to be doing my hood in the spring. 01264/771857

Posted: Mon Mar 26, 2007 3:03 pm

by DF9053

A quick update - the ash roof rail is made and in place, but I have not had a go at the cover yet - got cold feet over that at the moment.

So as I have the wings and other bits back from the paint shop I have put those on and rebuilt the front axle.

Cheers

Jeremy

Posted: Fri Jun 22, 2007 6:56 pm

by DF9053

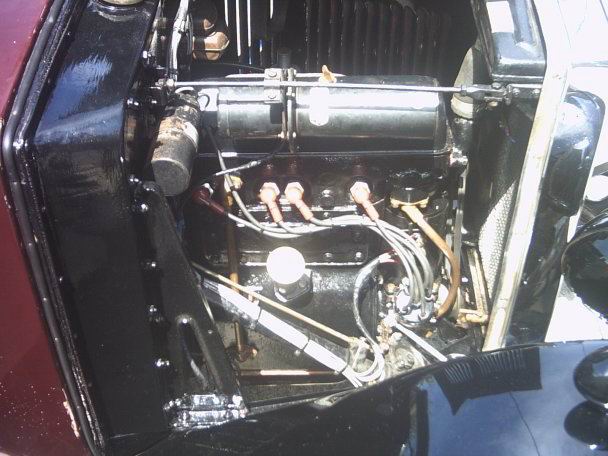

Rebuilt engine is now fitted, and just begining to put back all the remaining body work. Then I can carry out all the adjustments and book an MOT!

Posted: Sun Jun 24, 2007 6:33 pm

by DF9053

Some progress pictures:

Good oil pressure! Much better than 10psi before the engine rebuild.

Hopefully MOT this coming week.

cheers

Jeremy

DF9053

Posted: Wed Jan 02, 2008 6:58 am

by DF9053

Just changed the half shafts, the old ones were quite worn and one was twisted which could have resulted in a horrid rear axle expense!

I only noticed as the felt seals in the hubs needed to be changed, having oil all over the rear brakes, to change these as you know I needed to withdraw the half shafts - good job I think.

I have also fitted a fuel filter to catch the small sedimet from the tank, £1.50 from Halfords although it does not look very pretty!

I now need to do some more hot testing to see if the missfire has been cured, if not I have a replacement ignition coil to try.

Posted: Wed Jan 02, 2008 7:31 am

by DF9053

Posted: Wed Jan 02, 2008 4:32 pm

by chris lambert

Jeremy,

Minor rear brakes were not the slickest bit of design work I have ever seen-oil and brake drums are not a good combination! I (almost) cured the problem on my saloon by buying a sided pair (I think?) of axle shaft seals from Sports and Vintage made from nylon or plastic. My brother kept his diff oil (on his M) below the maximum level to stop it draining along the half shaft when stationary. The nearside drums are always contaminated a lot more than the O/S due to the camber of the road.

Chris

Posted: Wed Jan 02, 2008 4:51 pm

by DF9053

Chris,

I have bought some plastic shaft seals but they don't fit in the axle casing, they are too small and would need a sleeve made first - I don't have the facilities at present.

There are shaft seals on the inner ends of the halfshafts or there should be, but without taking the whole axle to bits you can't see them. The oil is also very thick, 140 grade! So I plan to keep the oil level lower and hope that this helps.

You can also now get sealed hub bearings which may help a bit as well. These are all tricks I will try on Y407 as I rebuild the back axle.

Posted: Wed Jan 02, 2008 5:40 pm

by prharris25

The best seals if you can find them are the Morris Eight cork seals (handed and with internal scroll).....not sure about availability these days though...probably autojumbles only now.

Re: DF9053 - Winter Work

Posted: Mon Jan 28, 2008 2:27 pm

by cammy

I think Harry Edwards has seals, the cork sort. I think they are about £7.5 a pair.